3D Printing/Additive Manufacturing

DMT SUMMER 2025 CLASS SCHEDULE

Additive manufacturing (also known as 3D printing) technologies are innovating rapidly across industry sectors. From its early applications for prototype development, additive manufacturing (AM) has evolved to produce customized, highly complex and industry-compliant end-user products. According to a recent publication by the World Economic Forum, global industries are projected to increase their use of AM technologies at an average annual rate of 20%. The potential of AM has received increased attention the United States.

The recently announced White House initiative, Additive Manufacturing Forward, will expand AM capabilities for small and medium-sizes manufacturers across the country. De Anza College is committed to preparing individuals for a full range of emerging occupations that employ AM, including 3D printing/AM and manufacturing engineering technicians.

De Anza College’s DMT Department was an early adopter of AM technology and has offered instruction in 3D printing since 1996. DMT's AM courses are continuously evolving to keep pace with the rapidly advancing 3D printing materials and processes. Faculty members work closely with local industry partners and government agencies to ensure that DMT curriculum is aligned with the latest technology.

To that end, DMT has been awarded a three-year National Science Foundation Advanced Technological Education (NSF ATE) grant to expand program offerings, internships, and employment opportunities in 3D printing/AM. Students in all DMT AM courses use professional-grade equipment and are taught by industry experts. De Anza's 3D Printing/AM program is designated a Stratasys certified training institution.

The 3D Printing/AM program offers instruction in the full range of printing technologies and materials, including polymers and metal, in active use by Bay Area R&D and manufacturing enterprises.

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- Fused Deposition Modeling (FDM) / (MEX)

- Material Jetting/PolyJet

Below is a listing of DMT's current course offerings in 3D Printing/AM. These courses, coupled with a solid foundation in CAD software and manufacturing technology, will prepare students for a wide range of occupations including additive manufacturing and engineering technicians. In fall 2022, De Anza College launched a new Certificate of Achievement in Additive Manufacturing Technology: 3D Design and Production. More details are found at the link provided.

3D Printing/Additive Manufacturing Course Descriptions

FREE software access to enrolled DMT students!

DMT 53: 3D Printing, Reverse Engineering and Rapid Prototyping

Course objectives

- Understand 3D Printing technology and it uses in industry since its inception in the early 1980’s

- Learn the fundamentals of 3D Printing materials and applications

- Grasp the operating principles, capabilities, and limitations of state-of-the-art 3D Printing methods.

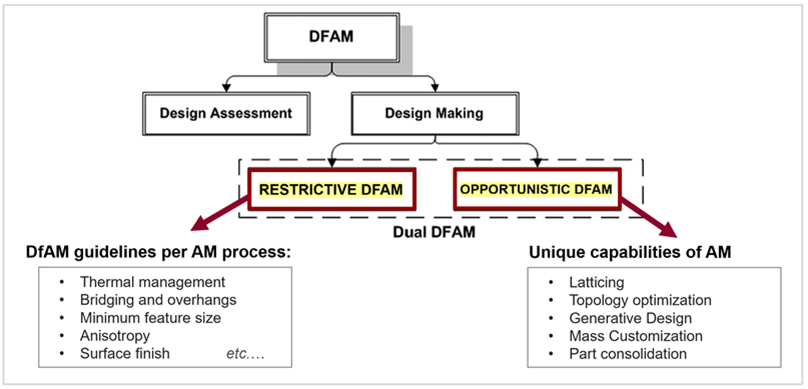

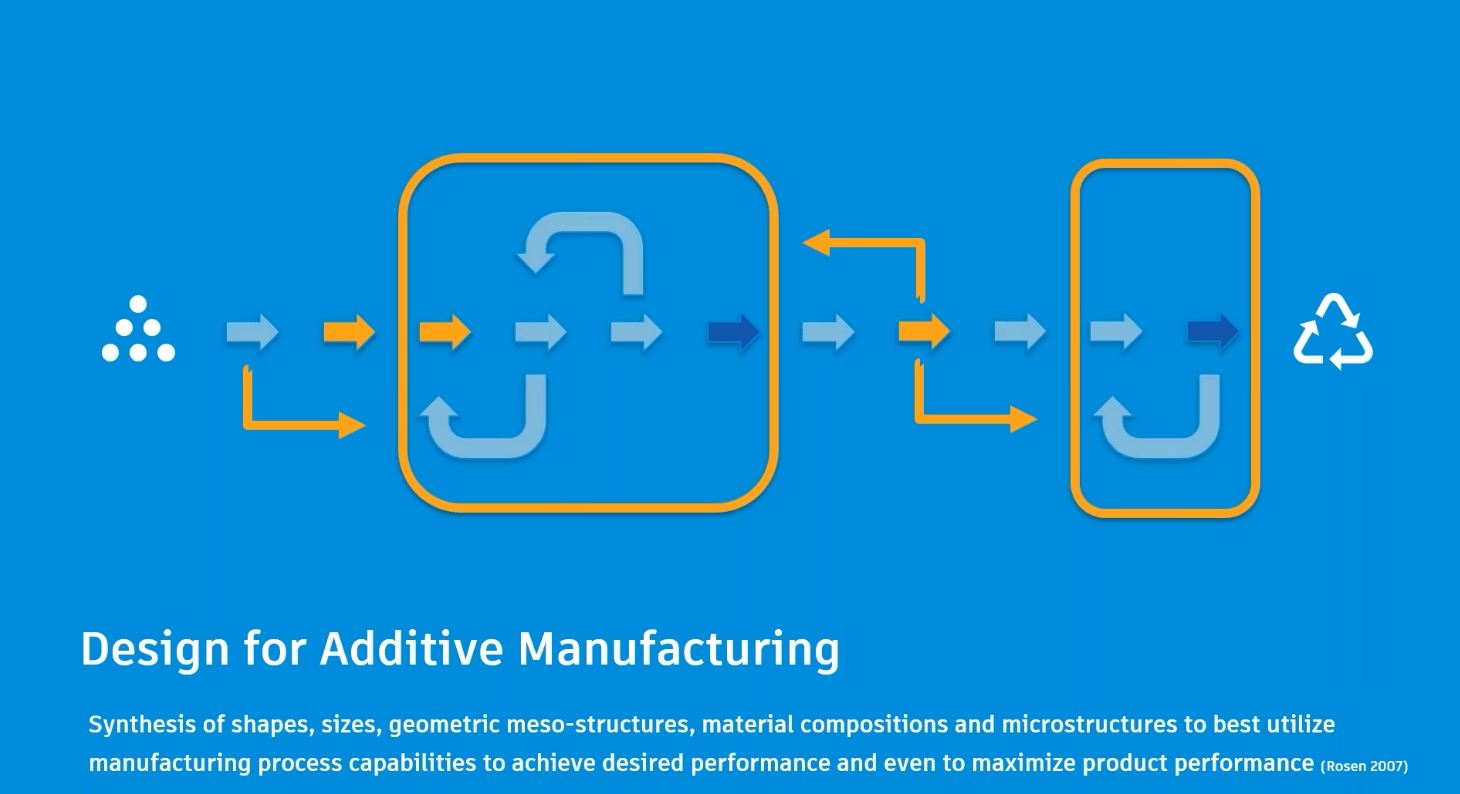

- Understand the principles of “Design for Additive Manufacturing” and compare and contrast additive processes with conventional manufacturing

- Understand Industrial grade and desktop 3D Printing machines and grasp the complete process.

- Realize applications of Additive Manufacturing and 3D Printing across major industries, products and understand the requirements and constraints of each through case studies.

- Realize the potential implications of 3D Printing technologies on product development and identify needs for new technologies to accelerate the advancement and impact of the new Rapid Prototype technologies

- Place 3D Printing in the context of the evolving rapid prototyping and manufacturing infrastructure and there developments in industry

- Explore the values and parameters of the major currently available technologies

- Understanding the basics of industry level CAD modeling tools and how they are used to interface with 3D printers as a tool to produce output data.

- Overview of laser scanning as a tool for reverse engineering and how it might be used to design manufacturing models for use in a 3D Printer environment

DMT 54: 3D Printing/Additive Manufacturing – Theory and Practice

Course objectives

- Recognize the advantages and limitations of 3D Printing and Additive Manufacturing technologies in developing new engineering systems and identifying emerging opportunities in developing products for mass customization products and processes

- Explore design processing parameters for the Additive Manufacturing process solution chain with available systems and software

- Utilize best practices in design intent and implement principles of “Design for Additive Manufacturing” or DFAM

- Explain the principles of material selection options for AM design considerations and tensile strength, heat deflection and ISO certification considerations

- Compare prototyping and product cycle considerations in the Additive Manufacturing process

Prerequisite: DMT 53

DMT 56: AM Support Tech Operator

Stay tuned as we look to the future and develop more 3D Printing / Additive Manufacturing curriculum to meet the educational and training needs of this fast growing industry sector.

- Forthcoming AM Certificate

DMT 57: DfAM

Questions?

Contact Mike Appio, DMT department chair, at appiomike@deanza.edu3D Printing Club at De Anza

- Visit our club website

- Want to join? Please email cad@deanza.edu

Learn With the Latest Tools!

De Anza DMT students have the opportunity to work with the following equipment and software.

Additive Manufacturing Equipment

|

Material Extrusion (MEX) FDM/FFF |

Design & Analysis Tools |

|

|

|

Powder Bed Fusion (PBF) SLS & MJF |

Material Jetting (MJT) PolyJet |

|

VAT Photopoly-merization (VPP) SLA/DLP |

Binder Jetting (BJT) |

Professional Application Software

- Autodesk Netfabb Ultimate

- Stratasys Insight

- GrabCAD Print

- 3D Sprint

- Sinterit Studio

- PTC Creo Parametric

- SolidWorks

- Siemens NX

- Creaform VXelements

- Fusion 360

- Autodesk Inventor

- nTopology

- Markforged Eiger

- PreForm

Technology Focus

See our class projects on YouTube

You're welcome to join our email list for information about classes and activities. Please send an email to cad@deanza.edu

Join us on LinkedIn